The main publicity image of Powermax booth this time highlighted the company's themes in technology leadership, product stability, talent advantage and community service, demonstrating the international development strength of Powermax to global peers. Qin Cangfa, President of Powermax said that there were two main reasons for Powermax' participation in JIAM: Firstly, there were a lot to learn from Japanese sewing machinery manufacturing, and participation in the exhibition could facilitate closer contact with Japanese companies and technologies at zero distance and learning their manufacturing philosophies and methods. Secondly, in the past few years, Powermax had made great improvement in product quality and other aspects and expected to showcase the brand and products to the entire Japanese market by this opportunity. "This is very important", said Qin Cangfa.

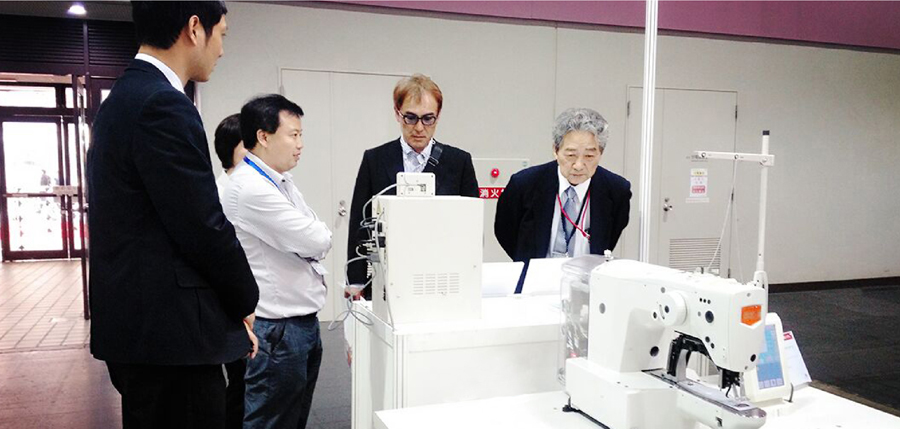

As the leading company in the electronic control field, Powermax made a stunning debut at the exhibition with a number of new products, including AHE59 four-generation lockstitch integrated electronic control, ASE59 roller integrated electronic control, ASE5A interlock integrated electronic control, MT30 bartacking integrated digital control systems, digital control system adaptable to 7300 high-end lockstitch machine, as well as other representative motor and LCD screen products. Among them, the MT30 bartacking integrated digital control system and digital control system adaptable to 7300 high-end lockstitch machine drive were the center of attention. MT30 was an innovative product launched by the company recently and attracted the attention of customers at home and abroad. Many companies came to consult and take pictures.

Qin Cangfa said: "The products debuted at the exhibition are more suitable for future industry development. In particular, some innovative parts, especially the servo digital system adaptable to Brother 7300 lockstitch sewing machine and PFAFF 1591 roller presser, are the latest development results of Powermax. Other exhibiting products, on the other hands, are advocating more on all-in-1 machine, perfect coordination of an electronic control system and a machine head, easy installation and low failure rate." It was understood that the original integrated machine was applied more in computerized sewing machine, which had been popularized in the market in the past two years. This time, Powermax extended the concept of all-in-1 machine to overlock, interlock machine and even other machine types such as bartacking machine with mature products. It put forward very high requirements for electronic control companies, and this represented the exact development trend of the industry and product form in the future.

For many years, Powermax has been committed to the servo control field, with the core goal of making the most stable and reliable servo control system in the world. The company continues to carry out technological innovation and product upgrade with the world's leading core technology system to provide full series servo control products for the sewing equipment industry. Participation in this exhibition is not only one of the company strategies to develop overseas markets, but also a way to strengthen communication and contact with Japanese, Taiwan and Southeast Asian enterprises, improving the brand influence of the company overseas.

At the exhibition, Qin Cangfa pointed out that "Intelligent manufacturing" and "Internet+" had become the development theme of the times. As a traditional manufacturing industry, the sewing industry has already started the prelude of intelligent manufacturing. Closely following the main theme of the times and relying on its own hard power, Powermax is committed to realizing intelligent, automated and networked electronic control products. Based on the Internet technology, the company's cloud system management system for sewing equipment under construction at present can provide more comprehensive after-sales and data services for garment enterprises through the big database platform and improve production efficiency. His views were recognized by visiting companies, many companies agreed and well-known foreign companies expressed their intention of cooperation.

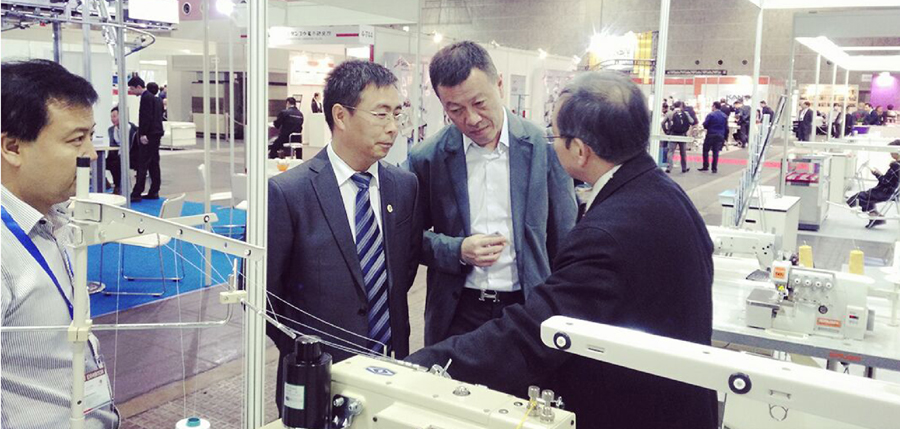

During the exhibition, sewing equipment dealers from various countries came to the company booth for consultation and negotiation. Powermax has taken a big step for expanding into the international markets.