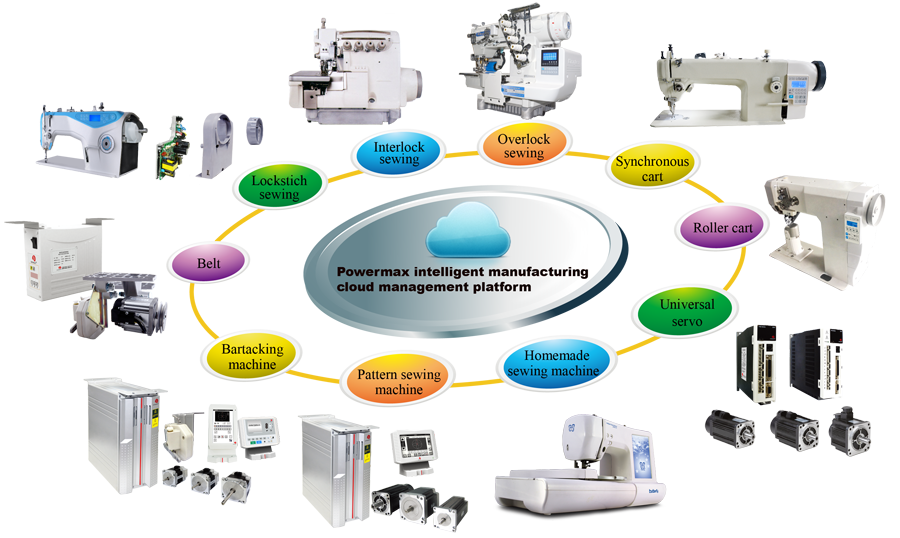

In this exhibition, Powermax launched the “Apparel Industry Smart Factory Solutions” that integrated the Internet of Things, cloud technology, big data analysis and efficient remote digital control system management into traditional factory to serve the development of apparel industry. Through smart factory, production process automation, business process systemization and production information digitization are implemented in stages to eventually realize the interconnection, agility, flexibility and intelligence of each production workshop.

- Through the intelligent production management system, workshop lean production and intelligent manufacturing are realized; the production capacity of the factory is improved;

- Integrated management and control, paperless and visualization of the entire garment processing and production process are implemented to improve the level of production management;

- Intelligent sewing equipment is applied to automatically complete the finished product counting and key process piecework functions;

- Traceability and visualization of the whole production process is achieved, improving the production efficiency and quality of products;

- Integrated, intelligent workshop personnel management and control is implemented to improve supervision efficiency;

- Personnel and equipment management are more in place to enhance production stability;

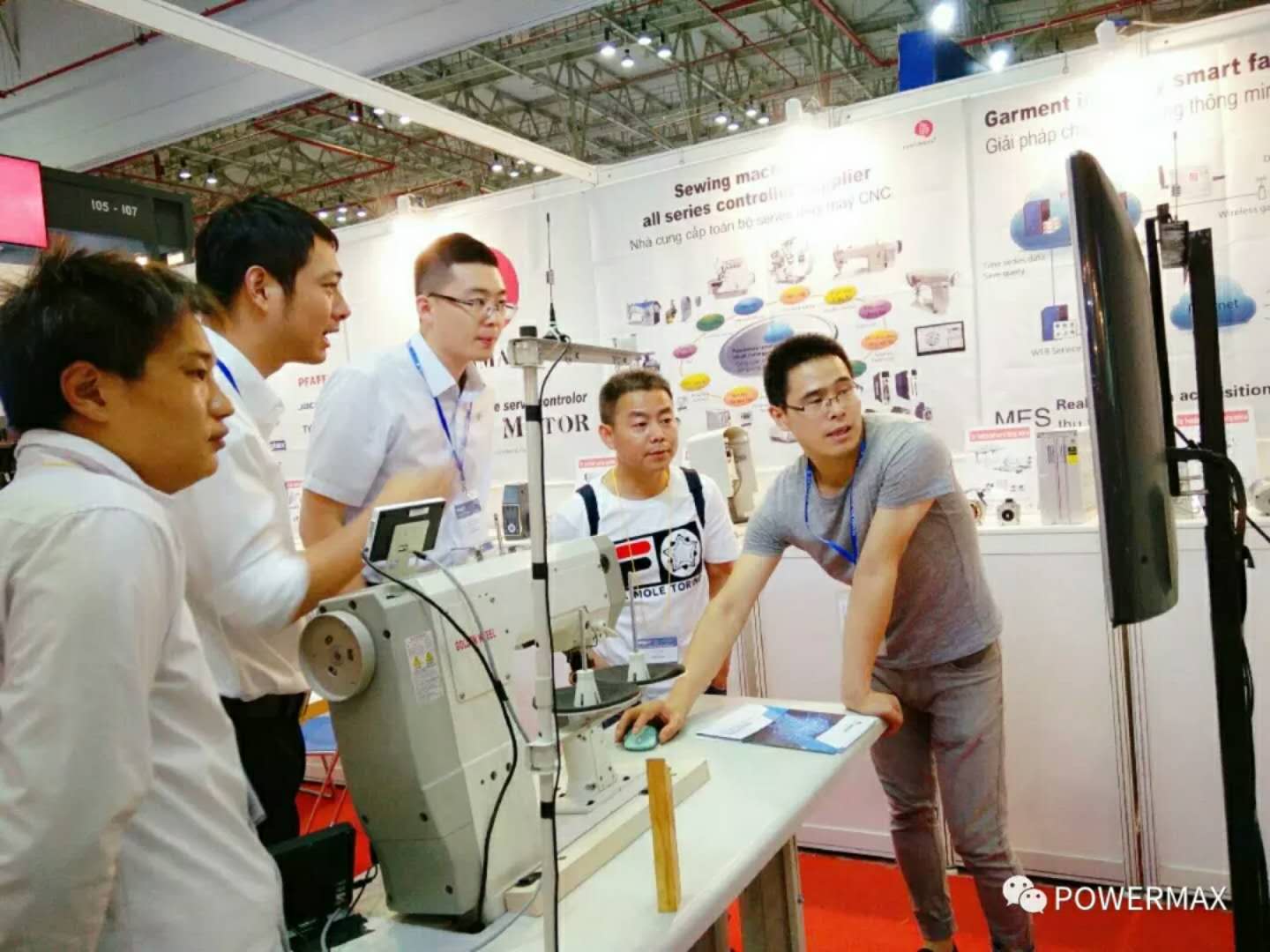

During the exhibition, Powermax staff also replied to the specific questions of visitors on the products and “Powermax Service Express” in details. The professional skills and enthusiastic service attitude of Powermax family received unanimous praise.

As a pioneer in the electronic control field and vanguard of intelligent sewing, Powermax has been leading the development of intelligent sewing. Powermax will continue to expand the territory and promote the vigorous development of sewing equipment industry.